Welding Rotator

High-Performance Welding Rotator Units

Welding Rotators are widely used in light and heavy fabrication Industry. They are mainly used to rotate and position the cylindrical jobs for circumferential welding (TIG/MIG/SUBARC) or for intricate assemblies. It consists of Drive Unit, Idler Unit and a Control Panel with Pendent. The speed can be controlled with the help of Variable Frequency Drive (VFD).

Features

- Easy to install.

- Easy to operate.

- Increase the production by reducing man power.

- Superior performance.

- Long functional life.

- Ensured good quality of welding.

Applications

- Pipe Welding.

- Pressure Vessels.

- Heat Exchangers

- Boilers.

- LPG Tanks.

Technical Specifications

| Units | 5 Ton | 10Ton | 20Ton | 30 Ton | 40 Ton | 50 Ton | 60 Ton | 80 Ton | 100 Ton | 150 Ton | 200 Ton | 300 Ton | |

| Rotating Capacity Drive Unit | Kg | 5,000 | 10,000 | 20,000 | 30,000 | 40,000 | 50,000 | 60,000 | 80,000 | 1,00,000 | 1,50,000 | 2,00,000 | 3,00,000 |

| Load Carrying Capacity Drive Unit | Kg | 2,500 | 5,000 | 10,000 | 15,000 | 20,000 | 25,000 | 30,000 | 40,000 | 50,000 | 75,000 | 1,00,000 | 1,50,000 |

| Load Carrying Capacity - Idler unit | Kg | 2,500 | 5,000 | 10,000 | 15,000 | 20,000 | 25,000 | 30,000 | 40,000 | 50,000 | 75,000 | 1,00,000 | 1,50,000 |

| Job Diameter Range | mm | 500 To 3000 | 500 To 3000 | 500 To 4000 | 500 To 4000 | 500 To 4000 | 500 To 4000 | 500 To 4000 | 500 To 4000 | 500 To 4000 | 500 To 4000 | 500 To 4000 | 500 To 4000 |

| Speed range (Surface Speed of Roller) | mm/min | 125 To 1250 | 125 To 1250 | 125 To 1250 | 125 To 1250 | 125 To 1250 | 125 To 1250 | 125 To 1250 | 125 To 1250 | 125 To 1250 | 125 To 1250 | 125 To 1250 | 125 To 1250 |

| PU Roller for Drive Size ('R' dia x 'T' width) | mm | 250 x 75 | 300 x 100 | 300 x 150 | 300 x 150 | 400 x 150 | 500 x 200 | 500 x 250 | 500 x 250 | 500 x 250 | 600 x 250 (Forged) | 600 x 250 (Forged) | 600 x 250 (Forged) |

Rotator Designs for Welding Applications

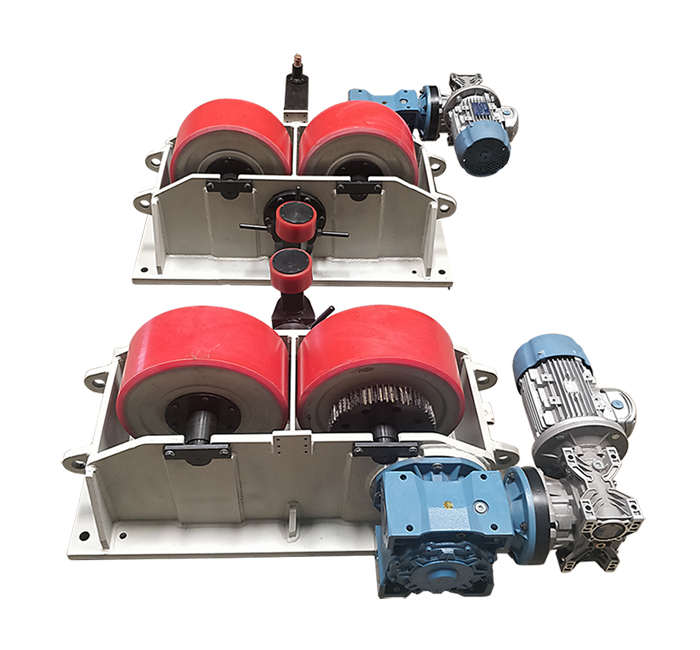

Self Aligning Rotators

Model – SAR Capacity Range : 1T – 300T

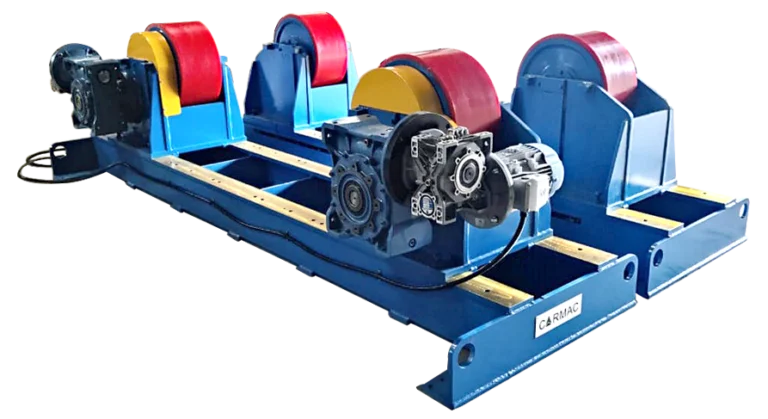

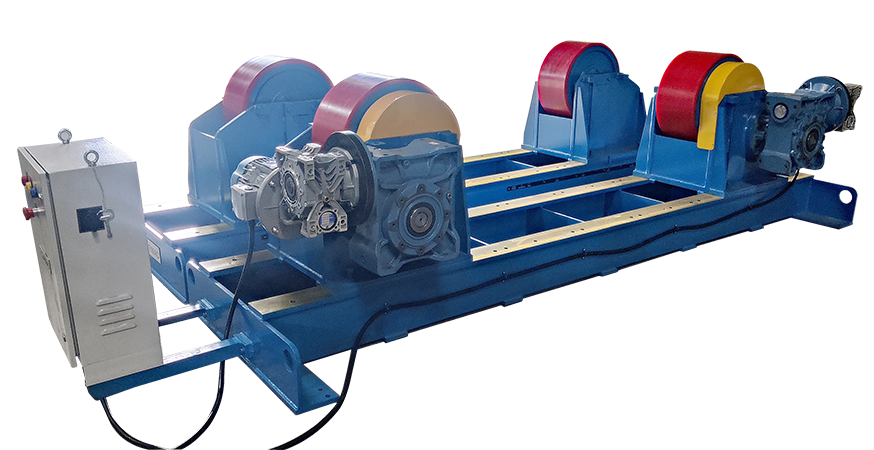

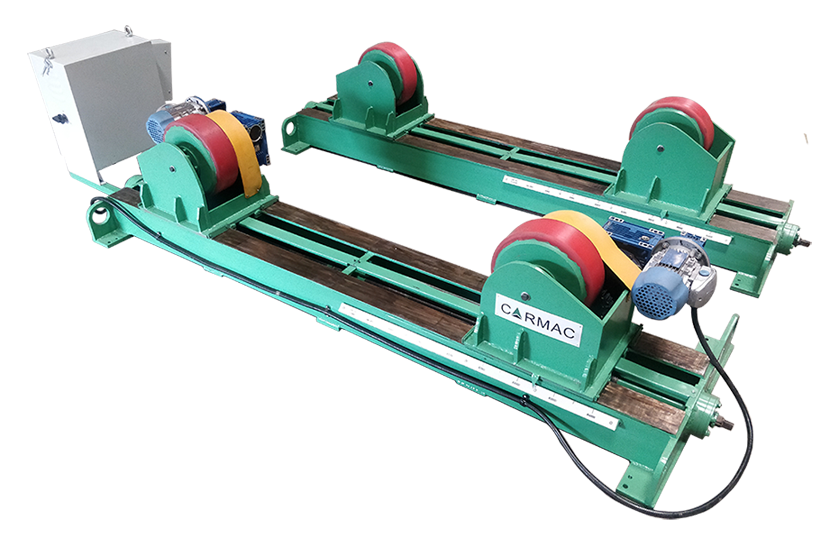

Conventional Rotator

Model – CR Capacity Range : 1T – 300T

Self Centering Rotator

Model – SCR Capacity Range : 1T – 300T

Customized Rotator

As per clients requirement Capacity Range : 1T – 300T